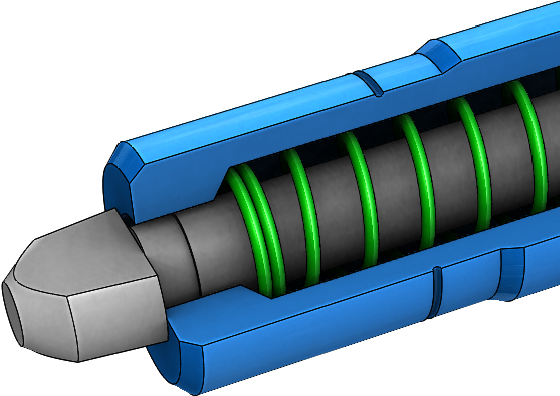

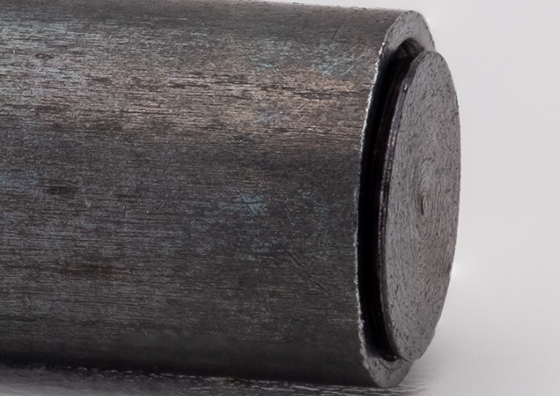

Research.

Development.

Production.

0

Awesome years

24 years in the market. Mainly thanks to the preservation of quality without compromise and using modern technology.

0

Completed orders

All requests, queries and orders are promptly addressed on the day they are received, or at the latest the following day.

0

Satisfied customers

The number of subscribers is evidence that GACZ is a stable partner for your company.

Looking for quality, responsibility, immediacy? Choose GACZ!

Discover quality, reliable, fast and affordable solutions.